What is a Variable Moment Driver/Extractor and How Does it Work?

It is a vibratory driver/extractor that has no amplitude, or moment (energy), when the hammer is started and stopped.

1) This is accomplished with the use of two sets of eccentrics, one set apposing the other set during start up and shut down.

2) These eccentrics are then, phased in and out of time with each other during operation creating amplitude or moment (energy). This infinite amplitude control is given to the operator for minimizing the radial vibration in the surrounding native soil and maximizing the drivability of the pile while limiting the impact on nearby structures. In addition the suppressor produces virtually no crane line vibration common with a standard driver/extractor, known as resonant vibration. Added to this feature is higher frequency (Hz), or vibrations per minute, which further lowers the size of soil vibration.

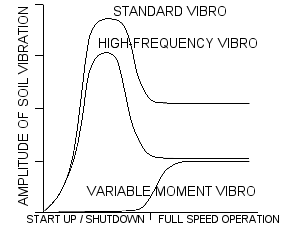

The start up and shut off of a standard driver/extractor has the highest impact on the surrounding soil. In the time that a standard driver/extractor takes to come up to full vibration speed, the amplitude (or size) of the soil vibration is three times larger than when the driver/extractor is at its full vibration speed. The same is true for when it is turned off and is a direct example of resonant vibration.

This graph shows the comparison of particle velocities for three driver/extractor types. Standard with a vibration speed of 1,600 VPM, high frequency operates at 2,100 VPM as does variable  moment driver/extractors. Vibration sensitive jobsites are the primary places variable moment driver/extractors are used.

moment driver/extractors. Vibration sensitive jobsites are the primary places variable moment driver/extractors are used.

Restrictions such as:

- An older foundation in close proximity to jobsite work.

- Seismically-sensitive business with sensitive equipment in use.

- Near occupied buildings.

- During non-standard work hours.

- Near medical clinics and hospitals.

- Close to curing concrete

- Around rivers with known spawning grounds.

- Near pipelines and utilities.

What is Resonant Vibration?

In order to understand resonant vibration, some basic terms used in describing the interaction of vibration in soil and structure need to be outlined.

Particle velocity is a name given to the measurement of amplitude size over time created by the vibration speed. (Represented in the driver/extractor comparison graph above) This mathematically described as inches per second (in/sec).

The slower the hertz (VPM) the more affect on soil and structure through resonance. 10htz (600 VPM) and below soil and structure start amplifying the particle velocity as the vibration passes through soil and structure and increase this in/sec size. This is why the start up and shut down of a standard driver/extractor can make the crane boom bounce. The suppressor amplifies the vibration during this slower frequency time. This affect led to APE’s patented two-stage suppressor, which minimizes the vibration by absorbing these slower frequency waves with double the line pull capacity. This same amplification takes place in soil and structures.

Seismic metering devices are commonly placed on structures around jobsites to monitor the PPV over the day’s work to protect against potential damage claims. High frequency and variable moment driver/extractors are used when the potential for structural damage is elevated.